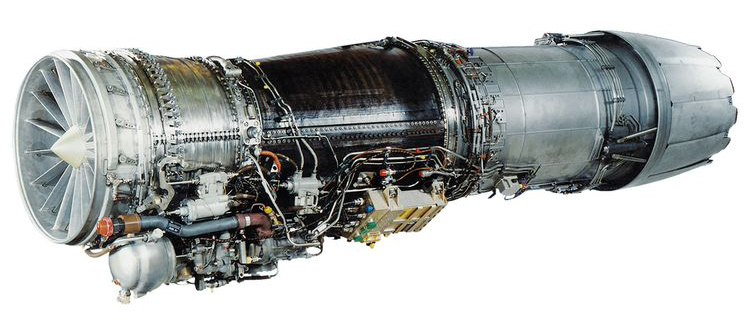

F414: Powering the Super Hornet

A further development of GE’s F404, the F414 combines advanced technology with the proven reliability, ease of maintenance, and operability of its successful predecessor. At the same time, it delivers 35 percent more thrust. The F414 powers Boeing’s F/A-18 Super Hornet twin-engine fighter and the E/A-18G Growler electronic warfare version, among others.

MTU’s involvement in the F414

The F414 was the first time that MTU took a risk and revenue share in a major U.S. military engine program. MTU produces various parts of the F414’s high-pressure turbine and low-pressure turbine.

Facts

- EIS: 1995

- The F414 is a two-shaft turbofan engine with afterburner in the thrust category 22,000 lbf

- Powder-metal turbine disks

- Single-crystal turbine blades

- Convergent/divergent nozzle

- Modular design

- Digital control unit

- On-condition maintenance

MTU competencies

- Program share: 2.9%

- Manufacture of high-pressure turbine parts and low-pressure turbine parts

Partners

- GE Aerospace

- GKN Aerospace

- Safran Aircraft Engines

Applications

- F414-GE-400: Boeing F/A-18 Super Hornet, Boeing EA-18G Growler

- F414-INS6: Tejas Light Combat Aircraft MKII

- F414-GE-39E: Saab Gripen Next Generation

- F414-GE-400K: KAI KF21 Boramae

- F414-GE-100: NASA X-59 QueSST (Quiet SuperSonic Technology)

Technical Data

| Max. thrust with afterburner | 22,000 lbf |

| Pressure ratio | 30:1 |

| Bypass ratio | 0.25:1 |

| Length | 12.8 ft |

| Weight | 2,450 lbs |