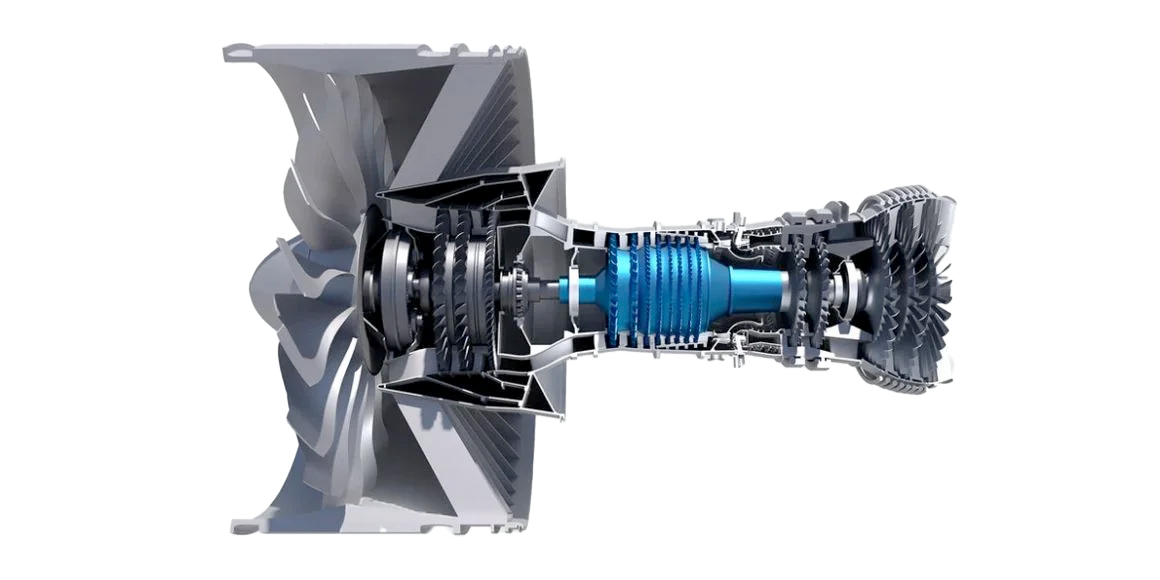

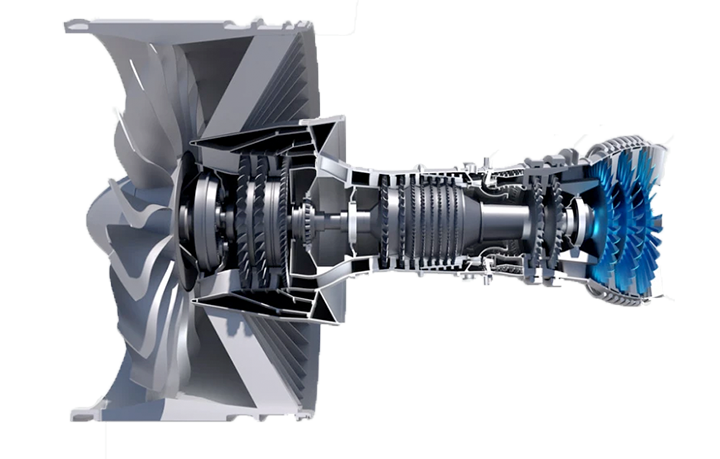

Compressors are the heart of every engine, and our expertise in this technology is virtually unparalleled: for over 50 years, MTU has been developing, manufacturing, and repairing high-pressure compressors (HPCs)—at the highest level. Our roots in this area lie in military aviation: from the Tornado’s RB199 engine to the Eurofighter’s EJ200 engine to the TP400-D6 in the Airbus A400M. We consistently developed this expertise and then transferred it to commercial aviation. Our commercial flagship is the high-pressure compressor of the innovative geared turbofan (GTF). With a pressure ratio of 15:1 and state-of-the-art optimized aerodynamics, it combines maximum efficiency with robustness. MTU’s involvement in the New Generation Fighter (NGF) also sees the company continue its tradition of military compressors. For this jet engine, MTU is developing and manufacturing the entire compression system—consisting of low-pressure compressor, inter-compressor duct, and HPC. And as part of the EURA joint venture, MTU is preparing the compression system for the next generation of European military helicopter engines.