Technical asset management

More and more aircraft and engines are being leased, which means the number and pace of transitions is also increasing. For owners and operators of engines, the top priorities are safety and asset value retention. They also want to be sure that they have the best possible technical support for their engines.

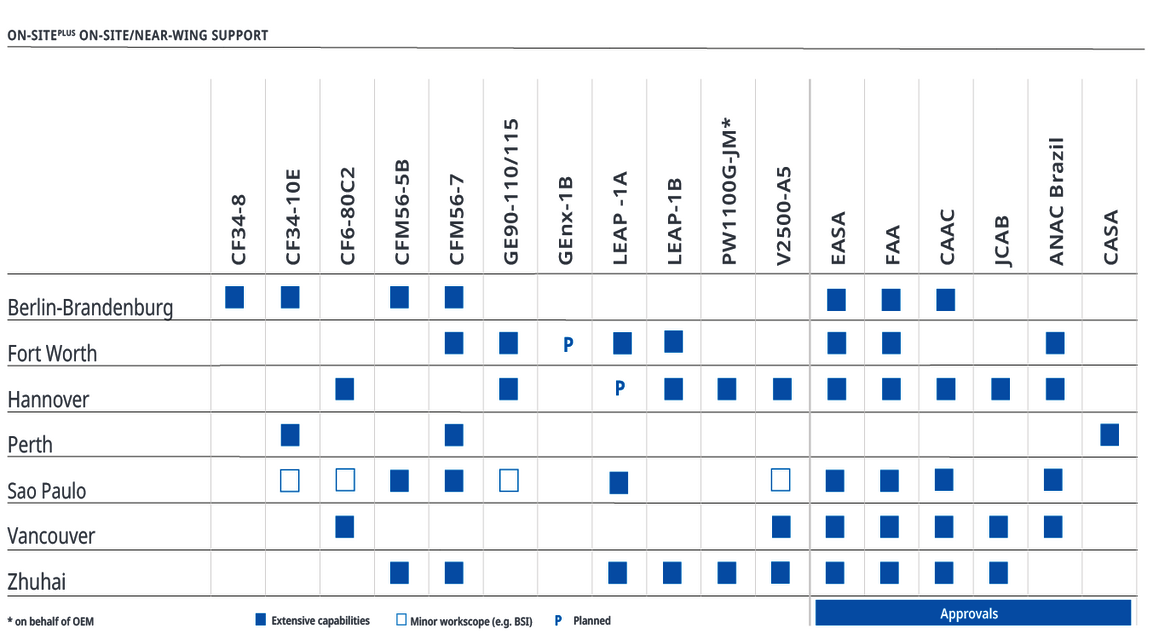

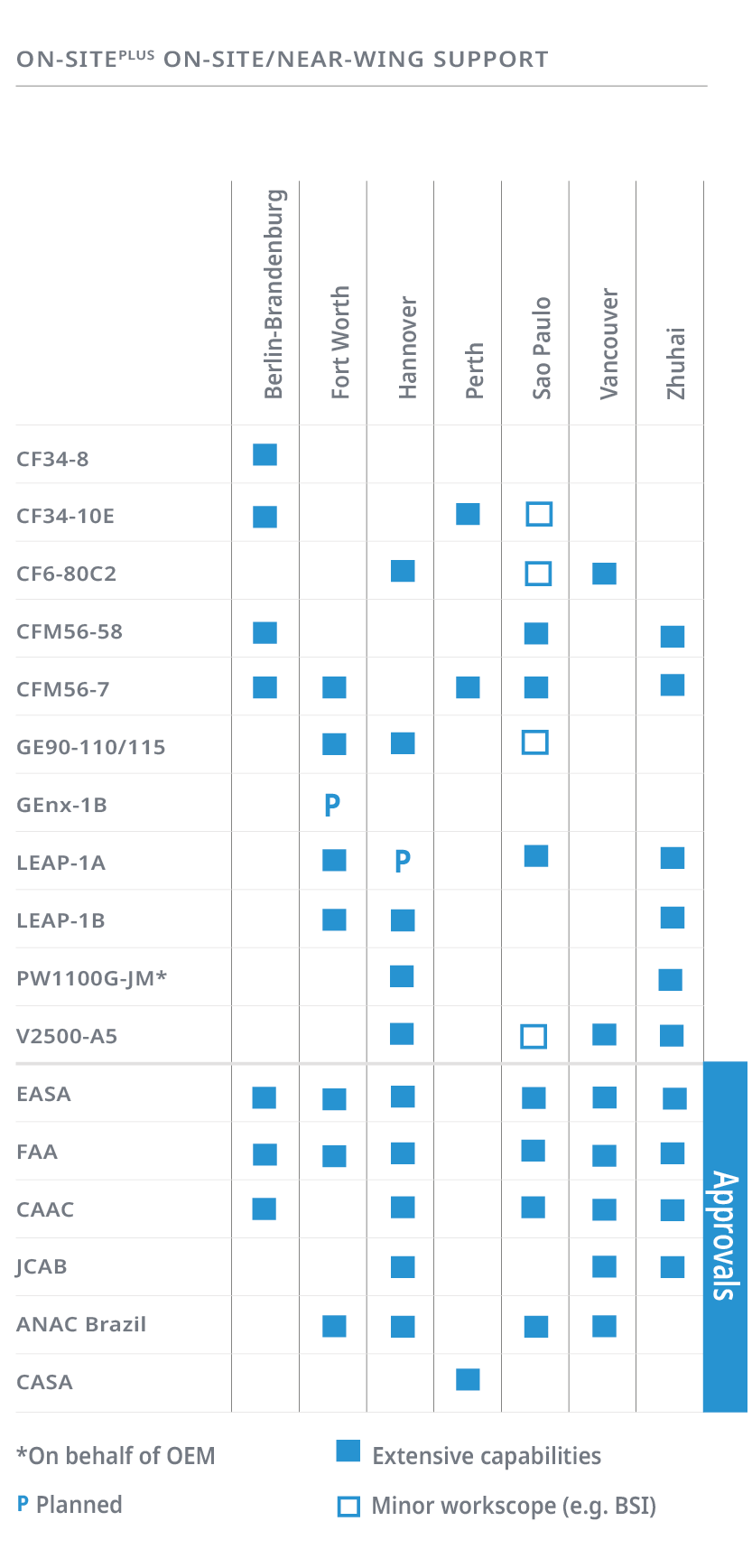

MTU Maintenance specializes in managing these valuable assets. Our technical asset management services (TAMS) offer our customers comprehensive and independent support—including technical consulting such as fleet and records management; logistics support with including specialist engine storage; and transition management services.

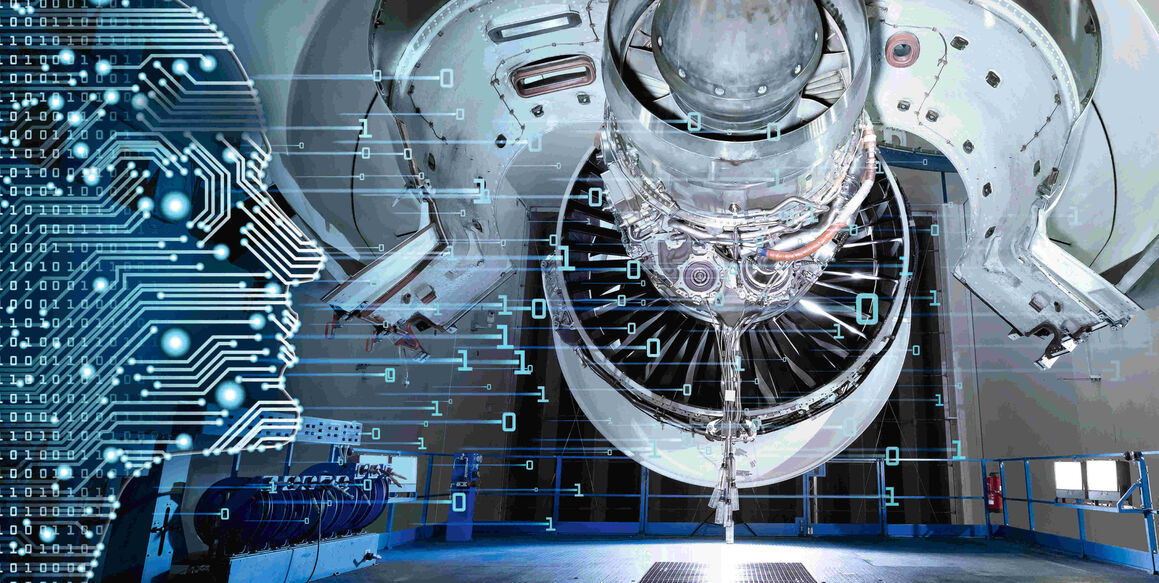

These services are fully supported by digital tools, such as WebETM 3.0 and CORTEX, MTU’s in-house developed AI-assisted fleet management software. In addition, we offer digitalized borescope inspections and records archiving.

Expertise you can count on: we help our customers minimize risks and optimize their operating and maintenance costs. On request, these services are available as modular and fully customizable packages, including MRO.

More information - product sheet