LM6000™

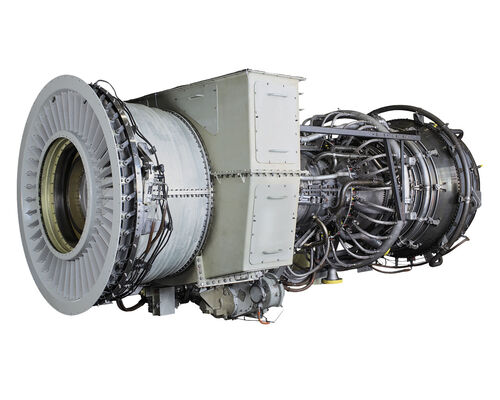

The LM6000™ industrial gas turbine is derived from GE’s CF6-80 aircraft engine. While it is mainly used in power generation, it can also serve as a direct mechanical drive for applications such as pumps. MTU Maintenance Berlin-Brandenburg has provided MRO services for this type of gas turbine since 1996.

The LM6000™ model features a five-stage low-pressure compressor (LPC), a 14-stage high-pressure compressor (HPC), an annular combustor, a two-stage high-pressure turbine (HPT), and a five-stage low-pressure turbine (LPT). As in the CF6-80C, the LM6000™ features a shaft that connects the low-pressure compressor to the low-pressure turbine. This coupled shaft also drives the generator.

GE has improved upon the LM6000™ by producing two new versions that are based on the CF6-80E: the LM6000PG™ with a single annular combustor (SAC); and the dry low emissions (DLE) LM6000PH™, which has a low-emission combustor with the fuel nozzles arranged on different levels.

MTU’s involvement in the LM6000TM

MTU is a risk- and revenue-sharing partner with a 13 percent share in the LM6000™ program and both derivative models. Compared to their predecessor, the LM6000PG™ and LM6000PH™ offer 25 percent more power and 18 percent more exhaust energy for combined processes or cogeneration. This marked upswing in efficiency lowers both fuel consumption and emissions.

By introducing the LM6000PF+, the latest addition to the LM6000 family, GE is responding to rising demand for flexible cogeneration solutions and broadening the application spectrum for gas and liquid fuels.

Facts

- Generator at “hot” or “cold” end

- Two-shaft design with direct drive, no separate power turbine

MTU competencies

- Manufacture of:

- Low-pressure and high-pressure compressor rotors

- Diffusor (conventional design)/Forward Outer Seal and After Air Seal (boltless-rotor design)

- High-pressure turbine blades

- High-pressure turbine vanes

- High-pressure turbine disk

- High-pressure turbine casing

- Thermal shield (conventional design)/Rotating Interstage Seal (boltless-rotor design)

- Low-pressure turbine blades

- Maintenance at MTU Maintenance Berlin-Brandenburg

Start year MRO: 1997

Shop Visits (2024): > 400

Workscope: Engine MRO

Applications

- Power generation

- Mechanical drive (e.g. pumps)

Technical Data

| LM6000PC (SAC) | LM6000PD/ PF (DLE) | LM6000PG (SAC) | LM6000PH (DLE) | LM6000PF+ (DLE) | |

|---|---|---|---|---|---|

| Power | 46.6/51.1 MW | 56/57.2 MW | 44.7/50 MW | 53.9/57.1 MW | 53.9/58 MW |

| Exhaust gas mass flow | 283 lb/s | 275 lb/s | 314,8 lb/s | 303 lb/s | 306 lb/s |

| Max. pressure ratio | 32.3:1 | 30.7:1 | 34.8:1 | 32.6:1 | 33:1 |