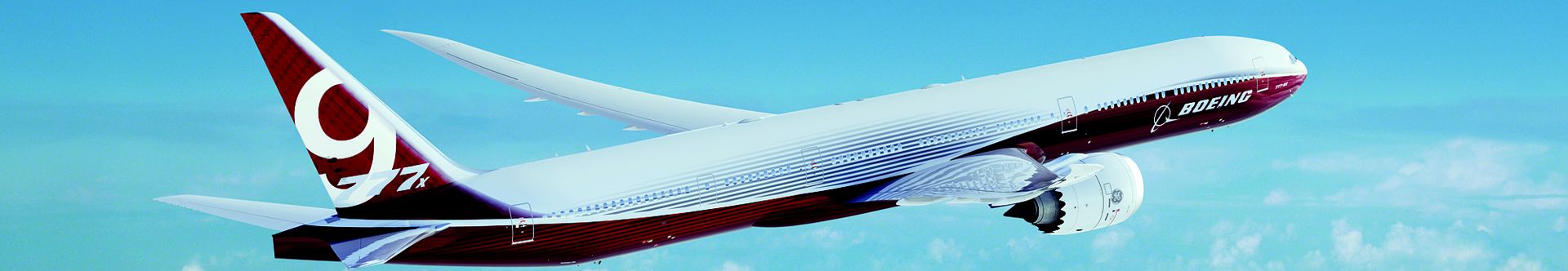

GE9X: Powering the Boeing 777X

The GE9X engine from General Electric (GE) represents the latest generation of propulsion systems for long-haul airliners, specifically the new Boeing 777X widebody aircraft. Based on the tried-and-true architecture of its predecessors, the GE90 and GEnx, the GE9X features the latest materials and technologies. It also sets new standards for efficiency: compared to its predecessor, the GE90-115B, it should achieve a 10 percent reduction in fuel consumption—and its CO2, NOx, and noise emissions will be significantly lower as well. At the same time, at rollout this will be the world’s largest and most powerful commercial engine.

MTU’s involvement in the GE9X

MTU has a 4 percent share in the GE9X program, with responsibility for developing and manufacturing the turbine center frame. For this module, MTU is drawing on its extensive experience participating in other engine programs, such as the GP7000 for the Airbus A380 as well as the GEnx for the Boeing 787 Dreamliner and the Boeing 747-8. The first turbine center frame development module was delivered to GE in January 2016, and the Boeing 777X is scheduled to enter service in 2026.

Facts

- EIS: planned

- The GE9X is a two-shaft-turbofan engine in the thrust category 100,000 lbf

- Built on proven GE90 and GEnx architecture

- Improved fuel efficiency, lower emissions

- Advanced materials, lower weight

- Lower noise emissions

MTU competencies

- Program share: 4%

- Development, manufacture and assembly of the turbine center frame

- Maintenance of the turbine center frame is planned

Partner

- GE Aerospace

Applications

- Boeing 777X

Technical Data

| Max. thrust | 134,300 lbf |

| Bypass ratio | 10:1 |

| Pressure ratio | 60:1 |

| Fan diameter | 11.2 ft |

| Fuel consumption (compared to previous version) | -10% |