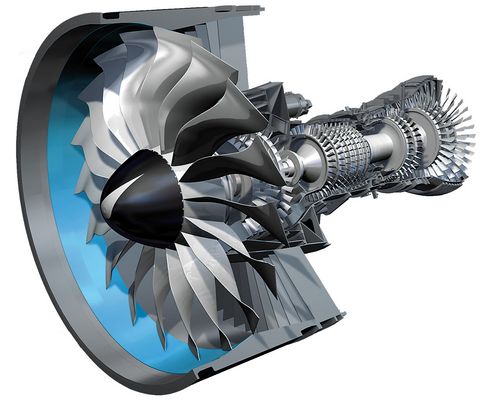

GTF engine: Powering the Airbus A320neo family, Airbus A220, and the Embraer E-Jets

The Pratt & Whitney GTFTM engine family jointly developed and built by Pratt & Whitney and MTU powers the Airbus A220 and A320neo family and Embraer's E-Jets. The reduction gearbox located between the fan and low-pressure compressor—on which the low-pressure turbine that drives the fan is mounted—allows the fan to rotate more slowly. At the same time, the low-pressure compressor and turbine can run faster. This helps achieve lower fan pressure ratios, and thus higher bypass ratios, and lets all components achieve their optimum performance. Consequently, the geared turbofan has very high overall efficiency. Compared to the previous engine generation, the GTF engine family represents a reduction in CO2 emissions of 20 percent with a noise footprint that is 75 percent smaller. A further advantage is that its fewer compressor and turbine stages make for a lighter engine.

Pratt & Whitney will launch the GTF Advantage™ engine configuration, unveiling a technologically improved geared turbofan engine for the A320neo family.

MTU’s involvement in the GTF engine family

MTU’s share in the GTF engine family is as much as 18 percent, depending on the application. In addition to being responsible for the high-speed low-pressure turbine and the first four stages of the high-pressure compressor, MTU also manufactures brush seals and nickel blisks for high-pressure compressor components that fall outside its design responsibility. Moreover, MTU in Munich is responsible for the final assembly of one-third of the production PW1100G-JM for the A320neo.

MTU competencies

- Program share PW1500G: 15%

- Program share PW1100G-JM: 18%

- Program share PW1900G: 15%

- Development and manufacture of various stages of the high-pressure compressor, of the high-speed low-pressure turbine and brush seals in all applications

- 1/3 of the final assembly of the PW1100G-JM series engines takes place at MTU Aero Engines in Munich

PW1100G-JM

- Maintenance at MTU Maintenance Hannover, MTU Maintenance Zhuhai, EME Aero and MTU in Munich

- Start year MRO: 2016

- Workscope: Engine MRO

PW1500G

- Maintenance at EME Aero

- Start year MRO: 2021

- Workscope: Engine MRO

PW1900G

- Maintenance at EME Aero

- Start year MRO: 2023

- Workscope: Engine MRO

Technical Data

| PW1500G | PW1100G-JM | PW1900G | |

|---|---|---|---|

| Thrust (lbs) | 19-25 k | 24,4-33 k | 19-23 k |

| Bypass ratio | 12.5:1 | 12.5:1 | 12.5:1 |

| Fan diameter | 6.1 ft | 6.7 ft | 6.1 ft |

Partners

- Pratt & Whitney

- Japanese Aero Engines Corporation (JAEC)

Applications

- PW1100G-JM: Airbus A320neo

- PW1500G: Airbus A220

- PW1900G: Embraer E-Jets Gen2

Facts

- EIS: 2016

- The GTF is a two-shaft turbofan engine in thrust category 14,000-33,000 lbf (capable of increase)

- 20% CO2 savings possible per trip with GTF-powered aircraft

- up to 50% reduction in NOx emissions

- up to 75% reduction in noise footprint