MTU Aero Engines AG

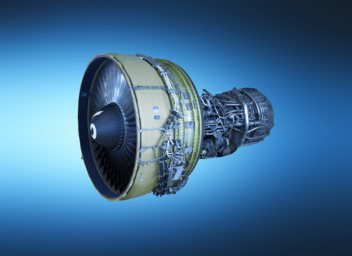

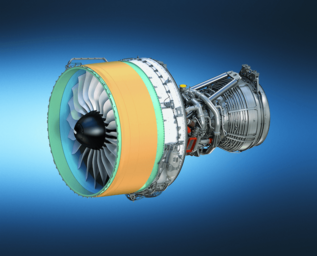

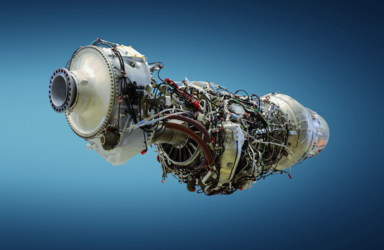

From its headquarters in Munich, Germany, MTU Aero Engines AG coordinates a global network of subsidiaries in addition to most of its development activities. The Munich site is home to multiple production halls in which we manufacture military and commercial engine components and assemble modules and engines. We set up a commercial final assembly line in 2016: one third of all Pratt & Whitney GTFTM engines for the Airbus A320neo are assembled in Munich.

Among the most important high-tech manufacturing processes at the Munich site are laser caving to produce cooling air holes in high-pressure turbine airfoils, as well as adaptive milling, friction welding and precise electrochemical machining (PECM) to manufacture nickel blisks. MTU developed both the PECM process and the machinery it requires.

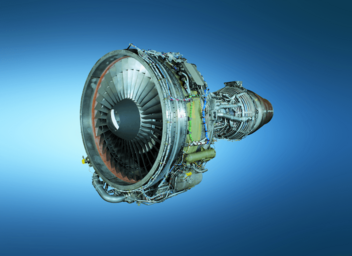

Other highlights include almost fully automatic systems for manufacturing turbine blades, for additive manufacturing and for high-performance test facilities. Our testing expertise is unparalleled in the world. We run tests for the development, approval, manufacturing and maintenance of engines, which involve testing material samples, components, engine components as well as the engine as a whole—commercial and military versions alike.

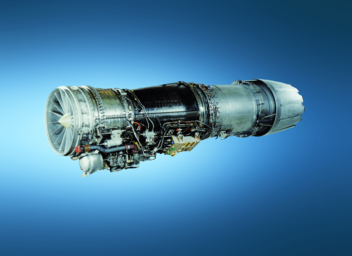

As the industrial lead company for the German Armed Forces, most of MTU’s military activities take place at its operational facility in Erding. Here, specialists from both organizations maintain EJ200 (Eurofighter Typhoon), RB199 (Tornado) and MTR390 (Tiger) engines.

Links & Downloads

Interested in our environmental statement?

Contact

80995 München

Germany

Fax: +49 89 1489-5500

Fax: +49 89 1489-5500

Are you interested in starting your career at MTU Aero Engines?