In principle, the environmental risks associated with deep geothermal energy are very low. The water is returned to the reservoir without further modification once its heat has been transferred to the heat exchanger. In Germany, the requirements and official specifications for the protection of the environment during the construction and operation of a geothermal plant are very high and are monitored intensively. The geological conditions of the deep subsurface in the Munich area are already thoroughly understood from numerous geothermal boreholes or from former deep wells for oil and gas. This means that in the Molasse Basin, drilling challenges arising from geologic uncertainties can be very well defined. The wells will be drilled in such a way that by means of several telescopically interlocked and concreted-in steel pipes, the boreholes are secured in a stable manner for the long term. This technique prevents the inflow of water or gas from the various strata through which the wells pass. During the drilling process, only substances will be used for which a risk to drinking water can be ruled out. Rocks from the wells, the water brought to the surface and the gases dissolved in it will be regularly tested for their composition during the drilling phase.

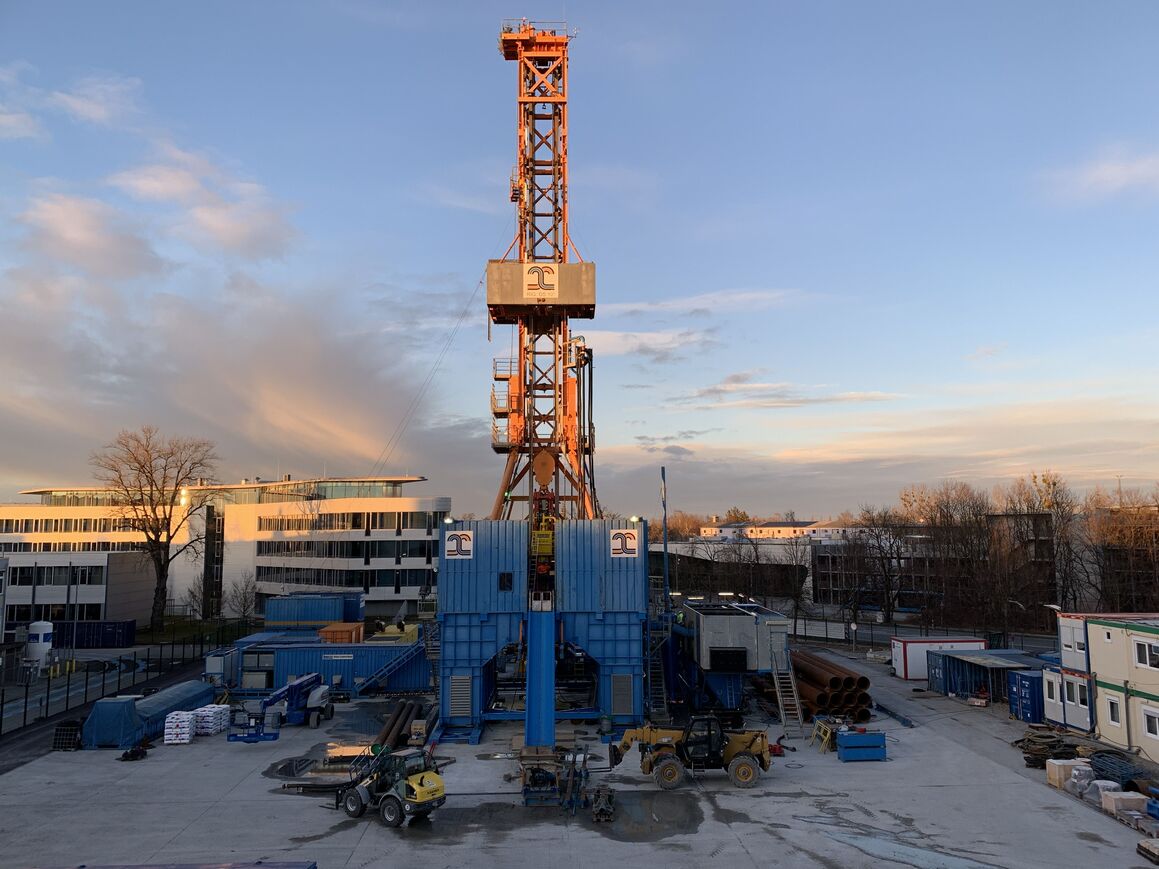

At the drilling site, additional structural measures are in place to prevent contamination of the soil even in the event of an accident (e.g. tank leakage). This includes a concrete surface with an appropriate drainage design, temporary storage tanks, inspection chambers and oil separators. The thermal water from the Malm itself is characterized by its low content of dissolved substances. Traces of oil or gas can sometimes be found in some geological strata or even in the Malm water. For this reason, the deep water will be routed in a closed system from extraction through heat exchange to recirculation. This will prevent the escape of any gases or substances that may be hazardous to the environment.