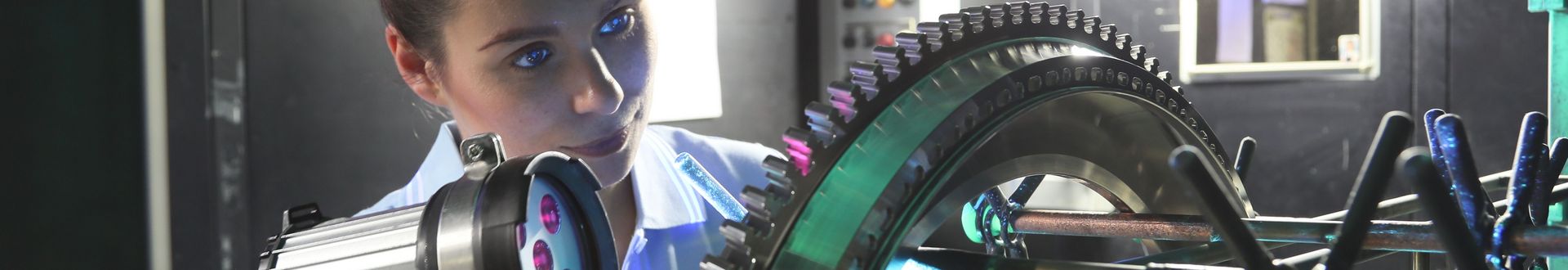

Environmental protection and climate action in manufacturing and maintenance

The most significant way we can help protect the environment is by means of ecologically efficient products. Environmental protection and climate action play a vital role in our manufacturing and maintenance activities, too. This is enshrined in the MTU Principles and has been established at our sites through a raft of ecological measures. Our understanding of responsibility is comprehensive: for the product as well as for its development, manufacture and repair. We are committed to the Paris Agreement and are systematically pursuing the transformation of our site operations.